gringing mills of iron ore

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日 — Two Swedish magnetite iron ores were comminuted with a pilot scale vertical-roller-mill. In these experiments the mill parameters dam ring height, grinding

[خذ المزيد]

Grinding iron ore concentrate by using HPGR and ball mills and

2022年3月19日 — ABSTRACT. An iron ore concentrate sample was ground separately in a pilot-scale HPGR mill in multiple passes and a dry open-circuit ball mill to increase the

[خذ المزيد]

Comparing strategies for grinding itabirite iron ores in

2021年3月15日 — A wide range of SAG and AG milling tests were conducted, with circuit configurations covering single and two stage, with and without pebble and pre-crushing,

[خذ المزيد]

Experimental investigation of the impact breakage characteristics ...

2023年4月1日 — Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrial-scale ball mills Powder Technology, Volume 392, 2021, pp. 489-502 Rodrigo M. de Carvalho , , Luís Marcelo Tavares

[خذ المزيد]

Comminution and classification technologies of iron ore

2022年1月1日 — Iron ore grinding and classification8.3.1. Examples of iron ore grinding and classification flowsheets. Compared to direct shipping hematite ores mined from the upper regolith, magnetite deposits are much finer grained and therefore require significant grinding to liberate the magnetite from its silicate matrix.

[خذ المزيد]

(PDF) Grinding Media in Ball Mills-A Review - ResearchGate

2023年4月23日 — Harder ores have a larger grinding re sistance than soft ores ther efore, hard ores have lower breakage rates than soft ores. Wear resistance depends on the stre ngth of the ore being ground [6 7 ].

[خذ المزيد]

Mechanistic modeling and simulation of grinding iron ore pellet

2021年11月1日 — The pilot-scale mill consisted of a 41.6 cm diameter cylindrical steel shell that was fitted with eight 13.0 mm width and 6.0 mm height rectangular lifters (Fig. 2).The mill was fitted with two exchangeable discharge end-plates, allowing for either overflow or grate discharge operation (Fig. 2).The dry ore entered the mill through a variable speed

[خذ المزيد]

Potential of High-Pressure Grinding Roll (HPGR) for Size

2022年3月16日 — 2.1 Experimental Design. The experimental planning with selected key factor like operating gap (X 1), applied load (X 2) and roll speed (X 3) was designed by CCD method to obtain the optimum conditions for grinding the BHQ iron ore in HPGR.A full second-order polynomial model was obtained by regression analysis for three factors by

[خذ المزيد]

Mechanistic modeling and simulation of grinding iron ore pellet

2021年11月1日 — Despite the important advances and application of these methods, their application in describing grinding in large-diameter (>7.5 m) mills has not been widely demonstrated. The work demonstrates the calibration of industrial-scale ball mill model parameters from laboratory milling tests on Platinum Group Metals (PGM) and Itabirite

[خذ المزيد]

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 — The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills. This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the

[خذ المزيد]

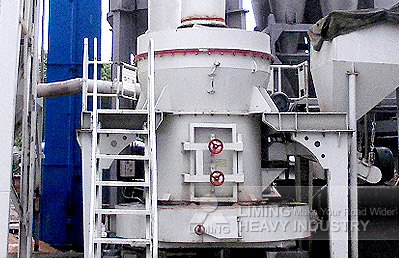

Research of iron ore grinding in a vertical-roller-mill

One contribution to minimise the increase is to use more efficient comminution equipment. Vertical-roller-mills (VRM) are an energy-efficient alternative to conventional grinding technology. One reason is the dry in-bed grinding principle. Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are presented here.

[خذ المزيد]

Mechanistic modeling and simulation of grinding iron ore pellet

2021年7月1日 — Grinding circuit data and ore samples were collected from nine industrial ball mills of diameters 3.2-5.5 m. For each of the ores tested there is a simple relation between the parameter and ...

[خذ المزيد]

Avoided energy cost of producing minerals: The case of iron ore

2019年11月1日 — For the grinding and re-grinding ball mills, we considered a survey of data regarding the specific energy (7.82 kWh/t) for these tumbling mills reported by Latchireddi and Faria [31]. For classification, the power of spirals and low and high magnetic separators were taken from [37] .

[خذ المزيد]

Comminution and classification technologies of iron ore

2022年1月1日 — Iron ore grinding and classification8.3.1. Examples of iron ore grinding and classification flowsheets. Compared to direct shipping hematite ores mined from the upper regolith, magnetite deposits are much finer grained and therefore require significant grinding to liberate the magnetite from its silicate matrix.

[خذ المزيد]

(PDF) Reducing Grinding Energy and Cost

The results of the analyses clearly shows that using a sieve of +180µm and its bottom -180µm, the best time for grinding 0.5kg of Itakpe iron ore with 3kg of grinding media and a mill speed of 92 rpm is 8 minutes, yielding

[خذ المزيد]

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日 — The application of vertical-roller-mills (VRM’s) for ore grinding is part of the second strategy. The grinding parts of a Loesche mill (Fig. 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring system.

[خذ المزيد]

Grinding of Itabirite Iron Ore in Autogenous and Semi-Autogenous Mills

The Brazilian iron ore resources are shifting from high grade ores with good liberation at coarse sizes, to lower grade ores with good liberation only at finer sizes, requiring grinding down to a fine size to liberate and concentrate. Considering the very large throughputs required in the plants it is important to ensure the long-term economic and energy

[خذ المزيد]

Effect of different mills on the fine grinding characteristics and ...

Such minerals require fine or ultrafine grinding to achieve effective liberation of the valuable metals. In this study, three laboratory-type grinding mills, including a ball mill, a vertical stirred mill and a horizontal stirred mill, were used to perform experiments on fine grinding and leaching experiments of gold ore.

[خذ المزيد]

Processing of Magnetite Iron Ores–Comparing Grinding Options

2009年1月1日 — The iron ore beneficiation plants normally include a series stages of size reduction (in order to achieve the desired liberation degree), increasing iron ore grade (magnetic separation), and ...

[خذ المزيد]

Comparing strategies for grinding itabirite iron ores in

2021年3月15日 — Request PDF Comparing strategies for grinding itabirite iron ores in autogenous and semi-autogenous pilot-scale mills High grade iron ore resources are becoming depleted in Brazil, with ...

[خذ المزيد]

Multicomponent modeling and simulation of the Minas Rio iron ore ...

2022年8月24日 — Multicomponent modeling and simulation of the Minas Rio iron ore grinding circuit. August 2022; Conference ... their application in describing grinding in large-diameter (>7.5 m) mills has not ...

[خذ المزيد]

Friction and wear of liner and grinding ball in iron ore ball mill ...

2017年11月1日 — An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing. The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which they fall onto

[خذ المزيد]

DEM investigation of SAG mill with spherical grinding media and

Semantic Scholar extracted view of "DEM investigation of SAG mill with spherical grinding media and non-spherical ore based on polyhedron-sphere contact model" by Changhua Xie et al. ... Effect of particle shape in grinding mills using a GPU based DEM code. ... Aiming at addressing the load behavior of iron ore particles in a ball mill, ...

[خذ المزيد]- كسارات عمودية للبيع الولايات المتحدة الأمريكية

- محمول خام الذهب المصنع مخروط محطم indonessia

- آلة تصنيع الرملفي الهند

- مصنع معالجة المعادن الذهب

- مطحنة مطرقة صغيرة مستعملة لتعدين الذهب للبيع

- تعمل من مصنع كسارة الحجر

- الكرة مطحنة للبيع الطين

- تشکیل ذغال سنگ انتراسیت

- مهندسی عمران رایگان تکنولوژی بتن پی دی اف کتاب

- طحن الحجارة والرخام في

- کارخانه آسیاب برنج در بنگلادش

- سات كسارة الحجر في

- الكرة مطحنة مواصفات الهند

- حجر محطم آلات سحق الصخور الصغيرة

- من متناهية الصغر طحن

- مصنع كسارة معدنية زرقاء في الهند

- كسارة سلسلة عالية الكفاءة

- مطحنة المطرقة محطم الفحم عمل

- ماكنة السلك البولنديه بشركه مصر للالومنيو

- سحق وطحن صفاء شبكة

- مثال على كسارة متنقلة

- آلة كسارة الحجر الأوتوماتيكية في مصر

- كسارة رخام رأس الخيمة

- من كسارة الفك مكون

- مقلع حجر جنوب أفريقيا

- فک برات سنگ شکن سنگ شکن فکی

- سنگ شکن هیدروکن برای فروش

© Copyright - PETER&X محطم